I brewed a re-modified version of MadelIPA on Saturday and had to make some on the fly changes. My last brew day had 95-100% humidity, so the amount of evaporation was nearly nothing, leaving me with a slightly more dilute beer than I’d planned. This time I wasn’t going to be caught off guard, so I lautered a larger volume than the 6 gallons called for, and since the gravity of the sweet wort was still in range, I figured no harm would be done. But after mixing the sweet wort, I took a gravity reading and found it to be near 1.040, lower than I was expecting, even with evaporation.

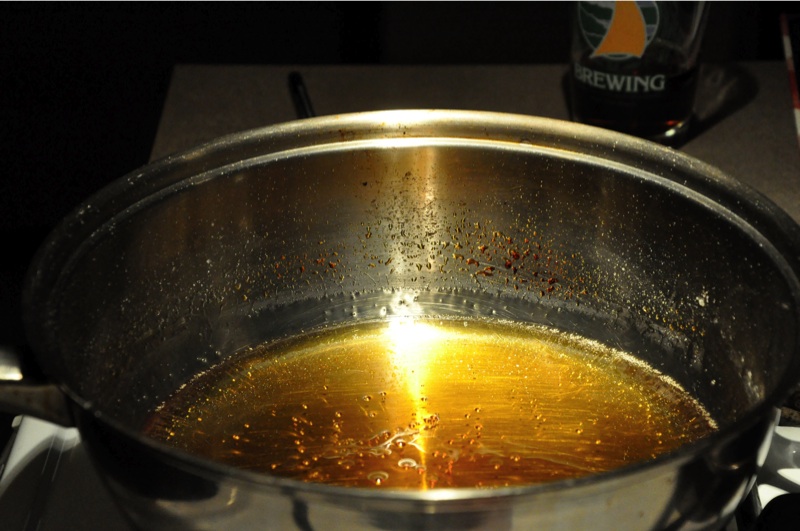

What to do? Turn the recipe in to a 90 minute boil, add some corn sugar and add more hops of course. Adding hops was a no brainer, but the corn sugar? Well, I had 3/4 lbs of it on hand, and a Pliny clone I found called for it, so I figured it was a safe way to up the OG without changing the body or flavor (hopefully). All said and done, the brew went well. I hit my strike tempurature just right so my mash temperature was spot on 152F.

Now the beer is sitting in primary bubbling, though krausen came on slowly. Not to get all finger-pointy, but I was using my first activator pack, and fermentation didn’t start until nearly 12 hours after pitching. That’s the price I pay for not having a starter on hand. I probably should have just dropped the dry yeast in.

Oh, and the extra hops were a good idea, at least for aroma’s sake. My basement smells delicious.